Sulphur

Dioxide - the Cidermaker's Friend

Sulphur dioxide or SO2 is the cidermaker's

friend. It has been used for hundreds of years (and possibly thousands for winemaking).

A quote I love to use is from John Beale, a contributor to

Evelyn's Pomona of 1664. He wrote:

“Lay

brimstone on a rag, and by a wire let it

down into the cider vessel, and there fire it; and when the vessel is

full of

the smoak, the liquor speedily pour’d in, ferments the

better”

In simple

terms what

happens is that the sulphur dioxide obtained from burning

sulphur (brimstone) inhibits or kills most spoilage yeasts, moulds and bacteria,

while

permitting the most desirable fermenting yeasts (such as Saccharomyces

cerevisiae or uvarum) to multiply and to

dominate the conversion to

alcohol. Only small amounts of sulphur dioxide are used, and its

effectiveness

depends quite critically on the pH of the juice (see below). Cider

juice,

when pressed, contains large numbers of yeast, mould and bacteria which

we do

not want and only a very few of those that we do. The sulphite levels

in the

table have been empirically established based on laboratory

investigations of

the sensitivity of these cider micro-organisms and the likely amounts

of

natural ‘sulphite binding’ substances in the juice,

in order to establish the

dominance of benign fermenting yeasts and hence a much reduced chance

of taints

and off-flavours in the finished product.

Sulphite is quite natural, occurring in the atmosphere in the gaseous

form of sulphur dioxide (SO2) as a result of volcanic processes, and in

the human body as a result of the breakdown of sulphur-containing

proteins during digestion. Many yeasts also produce it during

fermentation, reducing naturally occurring sulphate to sulphite. Of

course it can be toxic, even lethal, in the wrong dose and in the wrong

place, but so also can common salt and water.

The

form of sulphite used in cider or winemaking nowadays is as the

"Campden tablet",

or as sodium or potassium metabisulphite powder (which should not

be breathed in as it is irritant). In acid solutions such as

apple juice these materials liberate sulphur dioxide directly into the

liquid. (You can burn 'sulphur string' or 'suphur candles' in barrels

as Dr

Beale did, but it is impossible to be accurate with the sulphite dose

then). The amounts used are tiny, less than 200 parts per million

(ppm), and most of it gets quite rapidly bound up in the cider and

is no longer 'free'. Note that a very few people, principally

asthmatics, are

hypersenitive to sulphur dioxide in the free state which is why it is

labelled as a food allergen. Once bound in a beverage, it is no

longer a problem. The best documented cases of sulphite

sensitivity were from its use (now banned) at high levels on pre-packed

salads or pre-cut potatoes, where the high free SO2

levels could be a severe problem for asthmatics. The data on wine is

much more equivocal and where people have been challenge tested in

clinical trials far fewer of them prove to be sulphite sensitive than

they imagine. There are many other things in fermented beverages which

can cause adverse reactions, in addition to sulphite.

So.......how

much sulphite should I

add?

The effectiveness of sulphite depends very much on the juice pH. The Table below gives an approximate idea of how much sulphite needs to be

added to

a juice at a given pH before fermentation, depending on whether you

intend to

add a cultured yeast or allow the wild yeasts to do the job.

In

both

cases, addition of sulphite is important to kill bacteria, moulds

and adverse wild yeasts, while allowing the beneficial ones to

flourish. If a cultured yeast is added, sulphite addition

should

be made

12- 24 hrs before the addition of the yeast, or the added yeast will be

severely inhibited. Added cultured yeasts will start

within a day or two. If you are allowing wild yeast to build

up and to start the fermentation, you can use the 'total yeast

kill' dose in the left hand column, but the beneficial yeasts that

survive this may take several weeks to build up and get going. Things

will move quicker if you use the 'partial yeast kill' column, which

allows more wild organisms such as 'apiculate' yeasts to survive and will

give a different flavour balance. The dose is given both in parts per

million

of

sulphur dioxide (ppm or milligrams per litre) and the equivalent in

Campden

tablets per gallon (which are formulated so one tablet gives per gallon

gives 50 ppm). For more about the origin of Campden tablets click here.

It's

often

easier to use a stock solution of sulphur dioxide. To make a 5% stock

solution, dissolve around

10 grams

of sodium or potassium metabisulphite in 100 ml of water. (The

metabisulphite salts contain around 50 - 60% of available SO2

depending

on how they've been stored). Then 1 ml of this per

litre

of juice (5 ml per gallon) corresponds to 50 ppm (parts per million) of

SO2.

Note

that the correlation between titratable acid (TA) and pH is only

approximate

(as the graphs elsewhere make quite clear!). pH is the best measurement.

Sulphite Addition Table

|

pH

|

Approx TA

(% malic)

|

For

total yeast kill

(when adding cultured yeast)

|

For partial yeast kill

(for wild yeast fermentation)

|

|

SO2

(ppm)

|

Campden tablets

per gallon

|

SO2

(ppm)

|

Campden tablets

per gallon

|

|

3.0

– 3.3

|

1.2

– 0.8

|

50

|

1

|

nil

|

nil

|

|

3.3

– 3.5

|

0.8

– 0.6

|

100

|

2

|

50

|

1

|

|

3.5

– 3.8

|

0.6

– 0.3

|

150

|

3

|

100

|

2

|

|

>

3.8

|

<

0.3

|

add more acid!

|

add more acid!

|

150

|

3

|

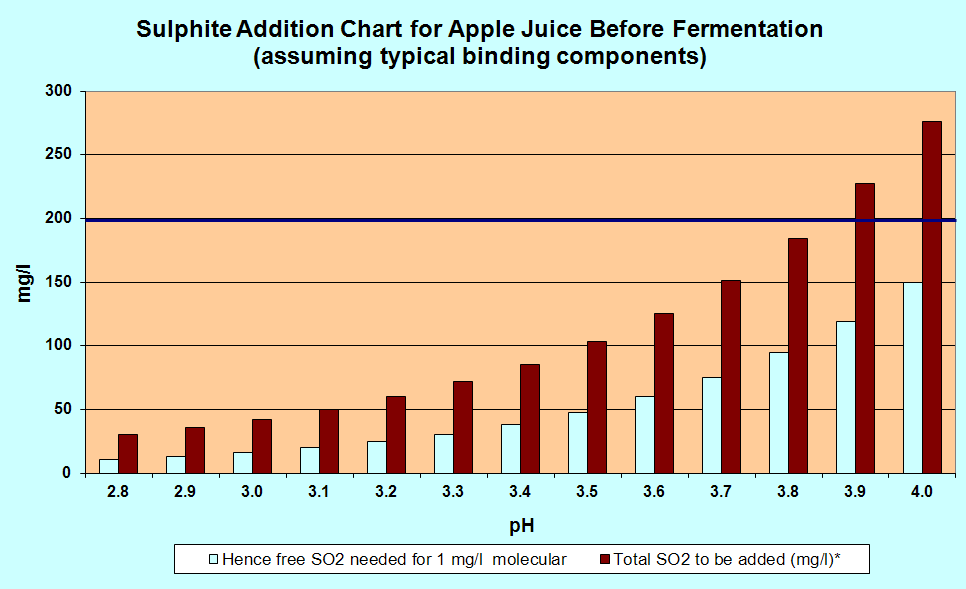

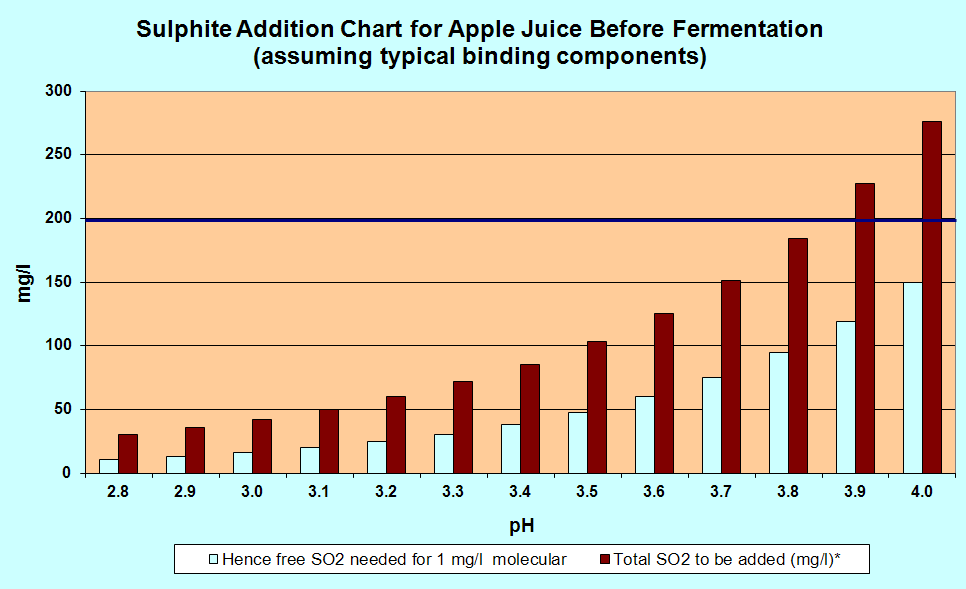

A more accurate chart

The

chart below gives the same sort of information, but is for those who

are measuring the pH accurately and dispensing their SO2 by volume from a stock solution and not by Campden tablets. The red bars give the amount of SO2 you need for a more or less total kill of the wild yeasts. If you want a partial kill, use only half the amount.

Addition of sulphite after fermentation

The table and chart above is

for use of sulphite as an antimicrobial before fermentation. Sometimes it is also used after

fermentation has all finished, at

racking, storage and bottling. The reason for this is partly

antimicrobial but also because it acts as an antioxidant. Or, rather,

it mops up the initial products of oxidation such as hydrogen peroxide

and aldehydes, preventing them going on to give sherry-like or

'oxidised' off-flavours. In those cases it is usual to add a

fixed amount of 50 ppm each time (up to the total legal limit of 200

ppm when all additions are summed together) with a view to achieving a

residual 30 ppm of free SO2 the next day. This is because the

antioxidant properties of sulphur dioxide are not affected by pH.

If you are planning to pasteurise a back-sweetened cider to stop it re-fermenting, the addition of 50 ppm SO2

at bottling also offers the benefit of blocking the Maillard reaction

between amino acids and sugars, which helps to minimse the development

of "cooked" flavours from the pasteurisation process.

How does sulphite work so selectively against adverse micro-organisms?

It's an interesting question - why does it act more effectively on the

'undesirable' yeasts and other microbes? The answer is not clear but it

seems that microbial sensitivity to sulphite is the norm and resistance

is a mutation. Most natural weak acid preservatives (eg vinegar (acetic

acid), benzoic and and sorbic acids) are believed to work by being able

to enter into microbial cells by molecular diffusion through the cell

membranes because they are in part lipophilic (fat soluble). Once

inside, they ionise and increase the acidity (lower the pH) and the

cell homoeostasis mechanism has to work very hard to pump out protons

to restore the pH. Eventually the cells become so exhausted that they

run out of ATP (their energy source) to do this and give up and die or

at least stop growing. Sulphite is believed to work in the same way as

other weak acid preservatives. In addition, it can bind to or disrupt

sulphur bridges in cell proteins, inhibit enzymes, and interfere with

DNA replication.

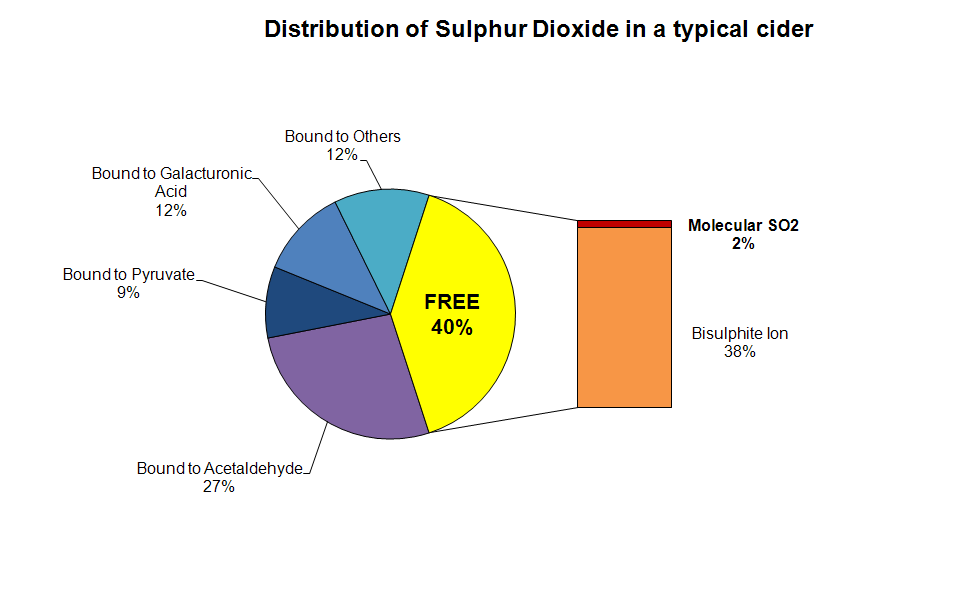

Sulphite-resistant organisms appear to have the ability to synthesise

acetaldehyde in response, more readily than other microbes. This binds

up the sulphite and makes it inactive hence it is neutralised and the

cell survives and continues to grow. It cannot be an accident that

acetaldehyde is a key intermediate (the last step in the chain) of the

synthesis of alcohol from glucose. In other words, the same mutation

which confers the ability to be a wine or cider yeast (smooth

fermentation of sugar to relatively high alcohol levels) entails the

facile ability to generate higher levels of acetaldehyde than normal,

which will bind up the sulphite and make it inactive. This is the

working hypothesis that most fermentation microbiologists go with.

More information for tecchies!

All the dosage information above is derived from long-standing work at the Long

Ashton Research Station and other wine research institutes, which

started in the 1950's and culminated in

the late 1970's. It is based on the empirical fact that the

level

of molecular SO2

required to kill adverse yeasts and bacteria but to allow

beneficial ones to flourish is around 1 part per million. To

get

this level of molecular SO2 you actually need a

lot more free SO2

because there is

a pH related equilibrium which keeps most of the SO2

in the

inactive bisulphite ion form. Hence, in the table and chart above, the amount of SO2

you need to add depends on the pH.

Unfortunately, that's not all the story. When you add SO2

to

juice or cider, some of it becomes bound

to juice components like glucose, galacturonic acid,

pyruvate

etc. Hence the total SO2 you need to add must

also take

account of this binding. It is the total

SO2

which is given in the

table and chart above. This is not an exact science because it needs to make

certain assumptions about the levels of the binding components, which

will differ depending on the nature of the fruit, how many rotten

apples got in etc etc! So the figures given in the table and chart are

necessarily approximate.

In the table, the column for total yeast kill is based on a target

value

of 1 ppm molecular SO2 and for partial yeast

kill is based

on 0.5 ppm.

Here's a summary which depicts the various forms in which SO2

might exist in a fermented cider after sulphite addition. The same general principles apply to a juice

before fermentation, though the binders are different. The most

important point is that only the small amount of molecular SO2 is actually effective as an anti-microbial.

If you want to know more, and to find out how that distribution is calculated, and you have software which can read Excel

spreadsheets, then download this file on

sulphite

binding and addition.

It contains three worksheets. The first one gives a table of

molecular, free and total SO2 at different pH

values (and is

more comprehensive than the table above). The second is just a

graphical representation of the free and total SO2

columns

(for a 'typical' apple juice) and is where the accurate addition chart comes from. The third worksheet gives more detail on

how the binding calculation is carried out. There are also

some

literature references given to show where the science comes

from

(and my publications page

also contains a

couple of downloads of relevant papers which should give some

further background, although they are focussed more on the addition of

SO2 to cider after fermentation than to juice

beforehand ).

Last edited 7th July 2011

Back

to the Contents

Page